Are Your Operations Fuel-Powered?

This Is What Waste Looks Like

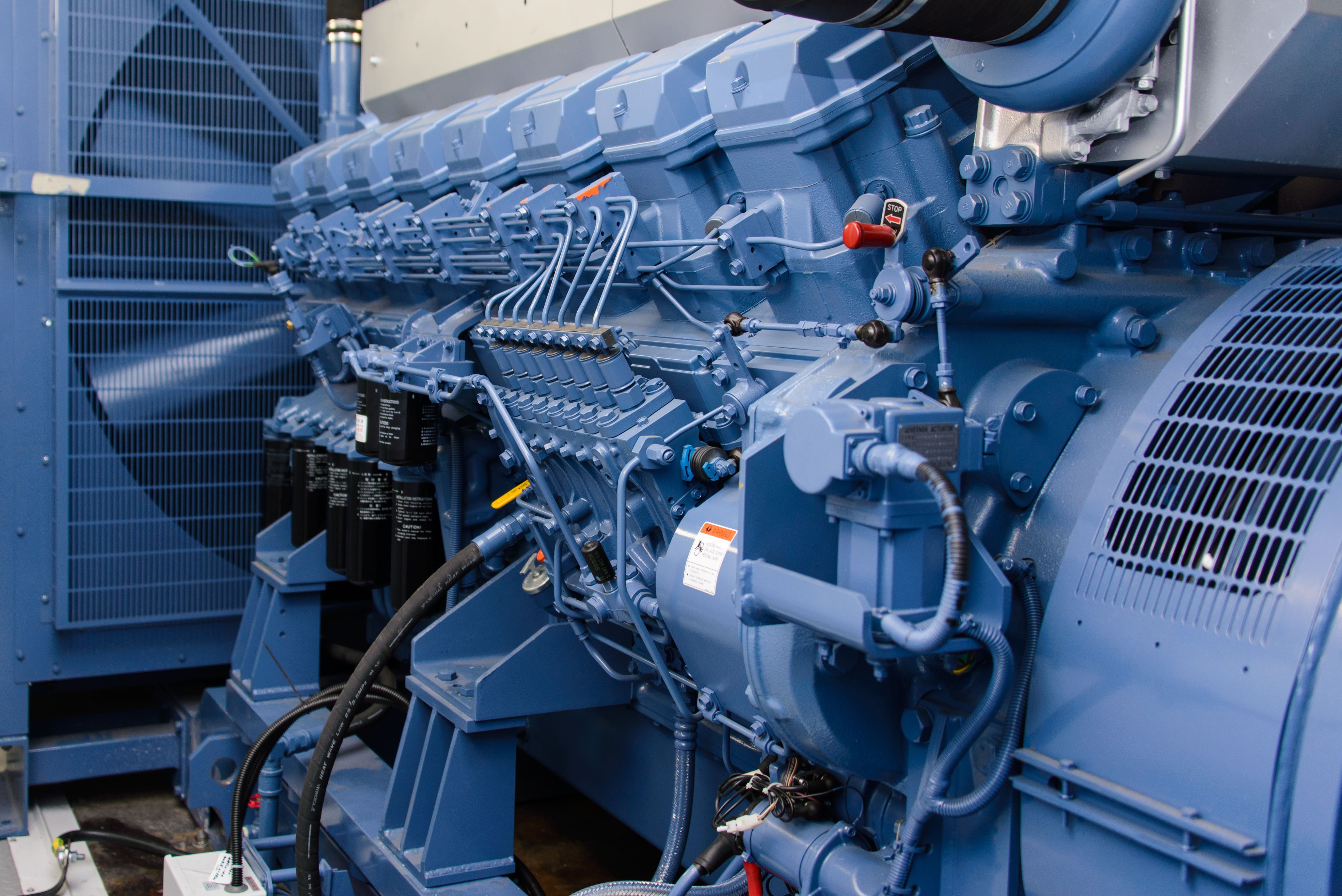

Petrol, diesel, biofuels - any liquid hydrocarbon fuel – struggles to completely combust. That means lost energy, more emissions, and avoidable engine strain. The black smoke you see? That’s just the visible part. The real cost hits your fuel bill, compliance, and performance.